At the HOTELEX International Food Logistics Exhibition held in Zhengzhou from August 8-10, 2025, the cold chain technology and equipment exhibition area became the focus of attention. As the global food supply chain transforms toward intelligence and greenization, cold rooms, as core infrastructure, have seen their technological iteration and scenario adaptability become key to industry competition. This article, combined with exhibition highlights, provides an in-depth analysis of five major cold room types and their breakthrough applications in the food logistics sector.

Technological Breakthroughs:

- AI dynamic temperature adjustment system: IoT sensors monitor 16 parameters in real time, including indoor temperature, humidity, and cargo density. Combined with AI algorithms to predict energy consumption peaks, compressor power is adjusted dynamically to achieve ±0.5℃ precision control.

- Phase Change Material (PCM) insulation layer: Composite insulation panels with R-value ≥8.0 reduce cold loss by 30% compared to traditional polyurethane materials. Field data from Tianjin Port Cold Chain Park shows a 42% reduction in nighttime standby energy consumption.

Exhibition Highlight:

XUEYUN's intelligent temperature-controlled cold rooms showcased at the exhibition achieve full-chain temperature traceability from raw material storage to end sales through blockchain technology. Successfully certified by EU BRCGS, they have become the preferred solution for export-oriented enterprises.

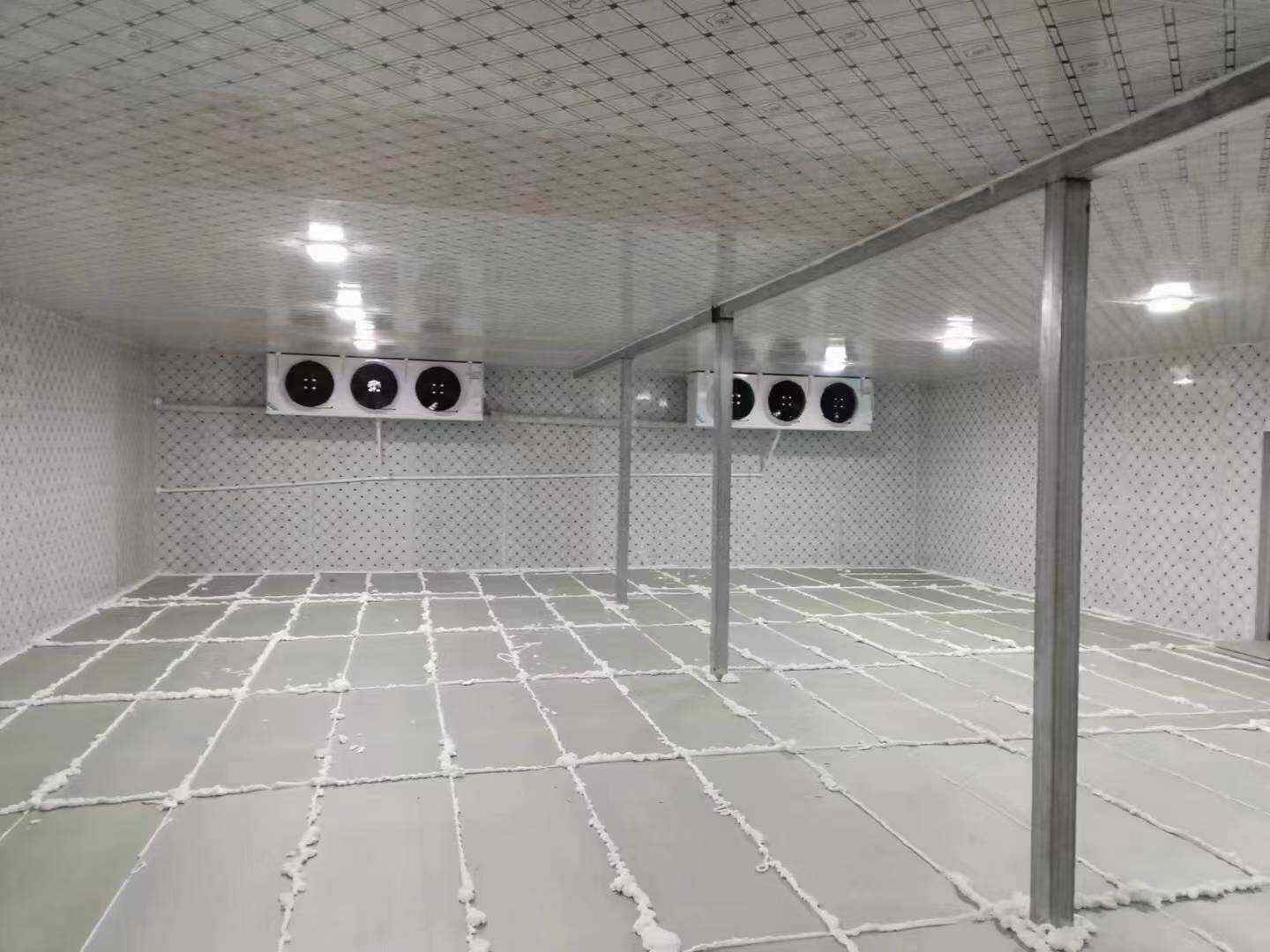

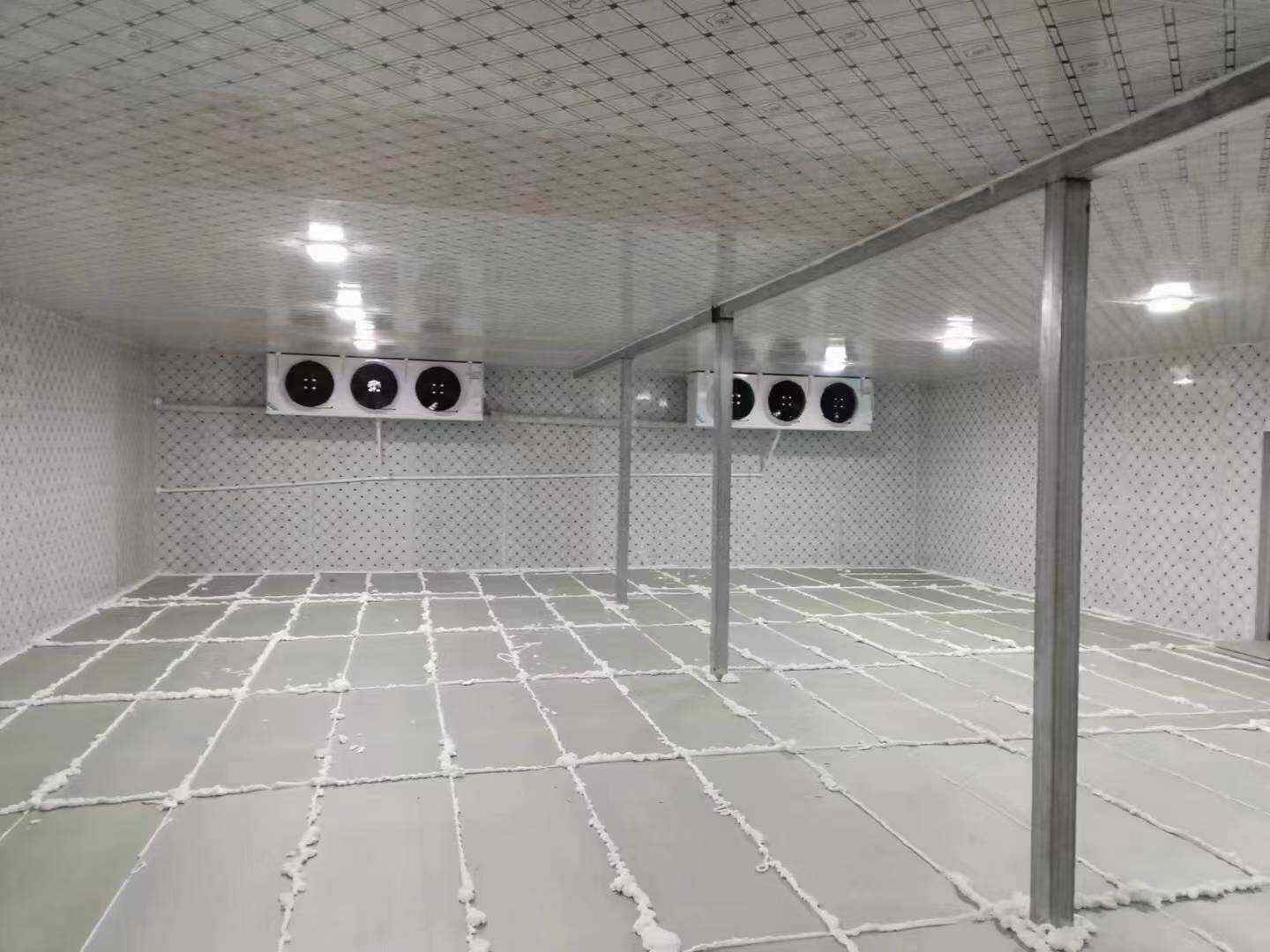

Core Advantages:

- 72-hour rapid deployment: Standardized prefabricated components enable on-site quick assembly, ideal for emergency scenarios such as fresh food e-commerce front warehouses and temporary medical supplies storage.

- Flexible expansion design: From 100㎡ basic units to 50,000+㎡ large-scale cold rooms, they support on-demand expansion, increasing storage capacity utilization by 25%.

Industry Application:

During the Zhengzhou exhibition, XUEYUN's modular cold rooms integrated CIP automatic cleaning systems, meeting both -18℃ freezing and 2-8℃ refrigeration dual-temperature zone needs. In pre-prepared food processing scenarios, they increased production capacity by 30%.

Technological Iteration:

- Mechanical refrigerated containers: Equipped with variable-frequency compressors and solar auxiliary power systems, they maintain stable -25℃ temperatures in high-temperature Middle Eastern environments, saving 35% energy compared to traditional equipment.

- Controlled atmosphere refrigerated containers: By adjusting oxygen/carbon dioxide ratios (O₂: 2-5%, CO₂: 10-15%), they extend cherry freshness to 45 days, doubling the shelf life of ordinary refrigeration.

Compliance Upgrade:

In response to EU F-Gas regulations restricting HFCs, multiple enterprises at the exhibition launched refrigerated containers using CO₂/NH₃ cascade refrigeration with GWP < 1, fully meeting 2025's latest environmental requirements.

Technical Parameters:

- -80℃ ultra-low temperature environment: Adopting two-stage compression + liquid nitrogen auxiliary refrigeration technology, it can reduce the core temperature of 35℃ beef to -18℃ within 3 hours, with cell damage rate as low as 0.8%—the industry's lowest.

- Full stainless steel sterile design: Welded joints feature arc treatment, and combined with UV disinfection systems, bacterial counts are controlled below 10CFU/mL, meeting EU Quality Milk certification standards.

Case Study:

XUEYUN's ultra-low temperature cold room case shared at the exhibition showed that waste heat recovery systems use compressor waste heat for office heating, saving 1.2 million cubic meters of natural gas annually and increasing comprehensive energy efficiency by 40%.

Compliance Design:

- Dual redundant refrigeration systems: Main and backup compressors switch automatically, ensuring vaccine storage temperature fluctuations ≤±0.3℃, meeting WHO pre-certification standards.

- GxP full-process validation: From insulation materials to temperature-humidity recorders, all components are certified by FDA 21 CFR Part 11 electronic signatures, supporting remote audits.

Exhibition Update:

XUEYUN's pharmaceutical cold rooms launched at the Zhengzhou exhibition integrate AI fault early warning systems, predicting equipment abnormalities 72 hours in advance. Combined with backup diesel generators, they achieve 99.999% operational reliability, becoming designated suppliers for international pharmaceutical companies.

Green Technology Leadership:

EU F-Gas regulations are pushing the industry toward natural refrigerants. CO₂ cascade refrigeration systems and photovoltaic-powered cold rooms dominated the exhibition. XUEYUN's ammonia/carbon dioxide two-stage compression system reduces carbon emissions by 90% compared to traditional HFC solutions.

Intelligent Logistics Integration:

XUEYUN's extreme cold environment unmanned forklifts (IP67 protection rating) showcased at SIAL Exhibition achieve fully automated warehousing at -30℃, increasing storage efficiency by 50%.

Regulation-Driven Upgrade:

The national standard "Cold Room Energy Efficiency Limits and Energy Efficiency Grades" implemented in February 2025 requires a 20% increase in refrigeration equipment energy efficiency, forcing enterprises to accelerate the replacement of old equipment. At the Zhengzhou exhibition, all XUEYUN's exhibited equipment have reached A+++ energy efficiency level.

Conclusion:

As a bellwether for the cold chain industry, three evolutionary directions for cold room technology: precision temperature control, modular deployment, and intelligent management. Whether serving instant delivery for fresh food e-commerce or ensuring absolute safety in vaccine transportation, choosing the right cold room type has become crucial for enterprises to build core competitiveness.

Contact us now to obtain XUEYUN's customized solutions based on cutting-edge technologies from the 2025 Zhengzhou Cold Chain Exhibition and seize the new track in green cold chains!

08.07, 2025

08.07, 2025