2025 Commercial Refrigeration Solutions: EU-Standard Compliant Energy-Efficient Cold Storage Equipment

In July 2025, the revised EU Energy-related Products Directive (ErP) and Switzerland's Energy Efficiency Ordinance officially came into effect, presenting the commercial refrigeration industry with the most stringent compliance challenges in its history. The new regulations not only require a Refrigerator Energy Efficiency Index (EEI) ≤ 25 and Air-Conditioning Seasonal Energy Efficiency Ratio (SEER) ≥ 5.80 but also mandate full life-cycle carbon footprint reporting, with standby power consumption required to be ≤ 0.5W. Against this backdrop, energy-efficient cold storage equipment that meets EU standards has become crucial for enterprises to gain a foothold in the market.

Core Energy-Saving Technologies: Reducing Energy Consumption at the Source

To meet EU energy efficiency standards, advanced energy-saving technologies are the core guarantee. In our commercial refrigeration solutions, the application of multiple innovative technologies has significantly improved equipment energy efficiency.

Variable frequency compressors are important tools for energy saving. Traditional fixed-speed compressors operate at a fixed power regardless of load size, resulting in significant energy waste. Our variable frequency compressors can adjust operating power in real-time according to temperature changes and load conditions in the cold storage. When the temperature in the cold storage is close to the set value or there are few goods, the compressor automatically reduces its speed to reduce energy consumption; when there are many goods or temperature fluctuations are large, it can quickly increase power to ensure refrigeration effect. Through this intelligent adjustment, 25-40% energy savings can be achieved compared with traditional fixed-speed compressors.

The application of high-efficiency insulation materials is also crucial. The phase - change material (PCM) insulated panels we use have much better insulation performance than traditional polyurethane foam materials. These panels have an extremely high R-value (≥8.0), which can effectively prevent cold air from escaping outward and reduce the operating time of the compressor. Compared with traditional materials, it can reduce standby energy loss by 30%, greatly improving the energy-saving effect of the cold storage.

In addition, our cold storage is also equipped with a heat pump device, which can recycle the waste heat generated during the operation of the compressor. The recovered heat can be used to preheat the heating in employees' offices or hot water for production, offsetting up to 30% of facility heating costs and realizing the cascade utilization of energy.

Compliance Certification Guarantee: Breaking Through Market Access Barriers

Compliance is the passport to enter the EU market. Our commercial refrigeration equipment strictly follows various EU standards in the design and production process and has obtained multiple authoritative certifications.

All equipment has passed EU CE certification, which means our products fully meet the EU's health, safety and environmental protection requirements and can freely enter the EU market. In terms of energy efficiency certification, our walk - in coolers and other equipment have reached A+++ level, far exceeding the energy efficiency bottom line specified in the new regulations, and have obvious advantages in market competition.

In response to the EU's carbon footprint requirements, the entire life cycle of our equipment from raw material procurement, production and manufacturing to transportation and installation is subject to carbon footprint tracking and reporting. We adopt low-carbon production processes and give priority to local suppliers to reduce carbon emissions during transportation. At the same time, our NH3/CO2 cascade systems use natural refrigerants with GWP < 1, which can reduce carbon emissions by 90% compared with traditional HFCs refrigerants, fully meeting the EU's strict requirements for environmental protection indicators.

Intelligent Management System: Improving Operational Efficiency

In addition to energy-saving and compliance design in hardware, the intelligent management system is also an important part of our commercial refrigeration solutions. Through the application of IoT technology, intelligent operation and management of cold storage are realized.

Our SmartCool™ mobile app allows users to monitor and control the cold storage anytime and anywhere. Users can adjust the temperature setpoints of the cold storage, schedule defrost cycles through their mobile phones, and view energy reports in real-time. This not only reduces the workload of manual inspection but also can find and deal with problems in time to avoid energy waste. A European frozen food distributor reduced maintenance costs by 62% by using our intelligent management system.

The AI - powered fault detection function is even more 保驾护航 for the stable operation of the cold storage. Sensors monitor more than 16 parameters such as compressor vibration and refrigerant pressure in real-time, and analyze the data through AI algorithms, which can issue early warnings 72 hours before equipment failure. This gives maintenance personnel sufficient time to prepare and repair, greatly reducing downtime caused by equipment failure and ensuring the continuity of the cold chain.

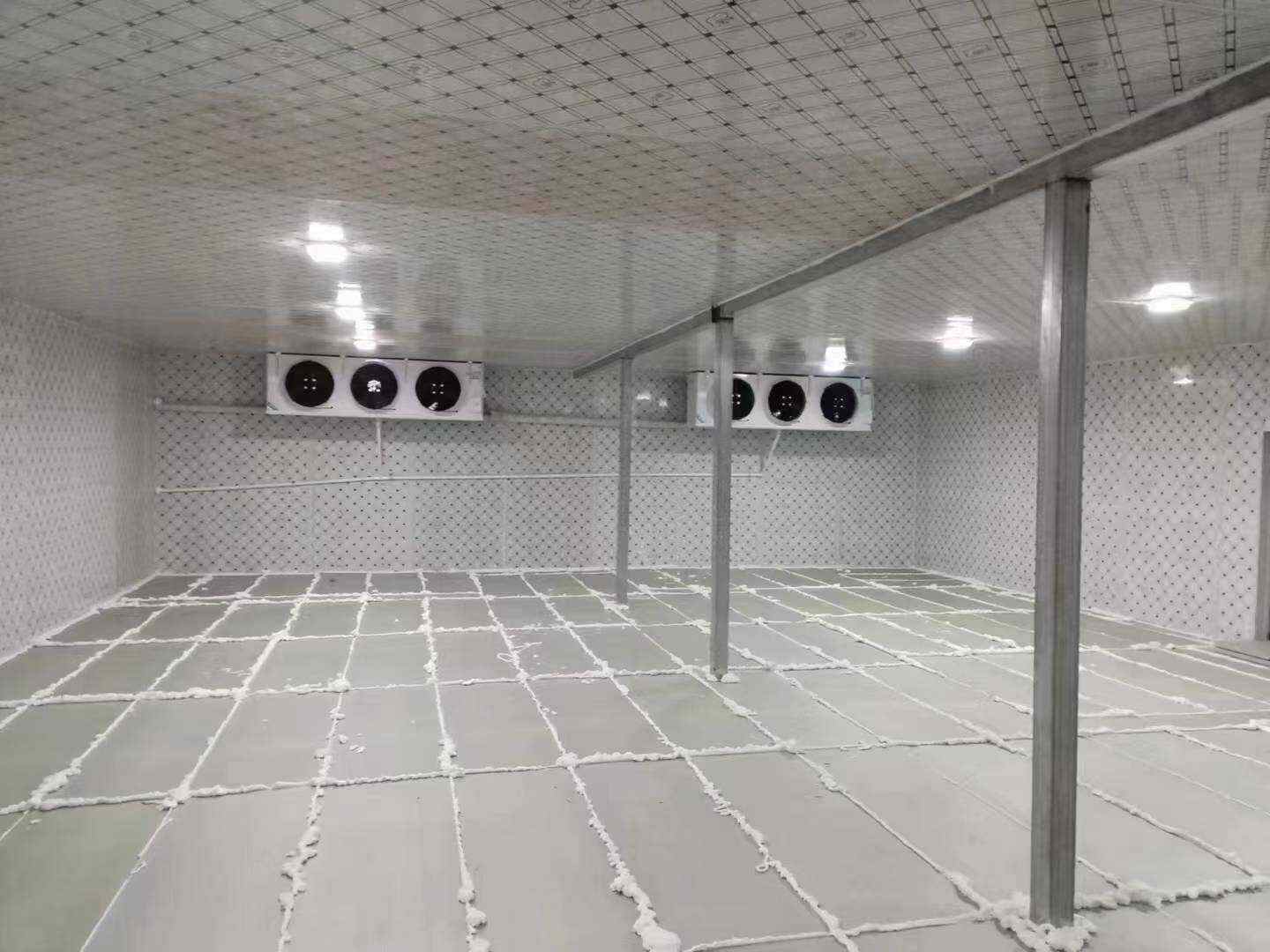

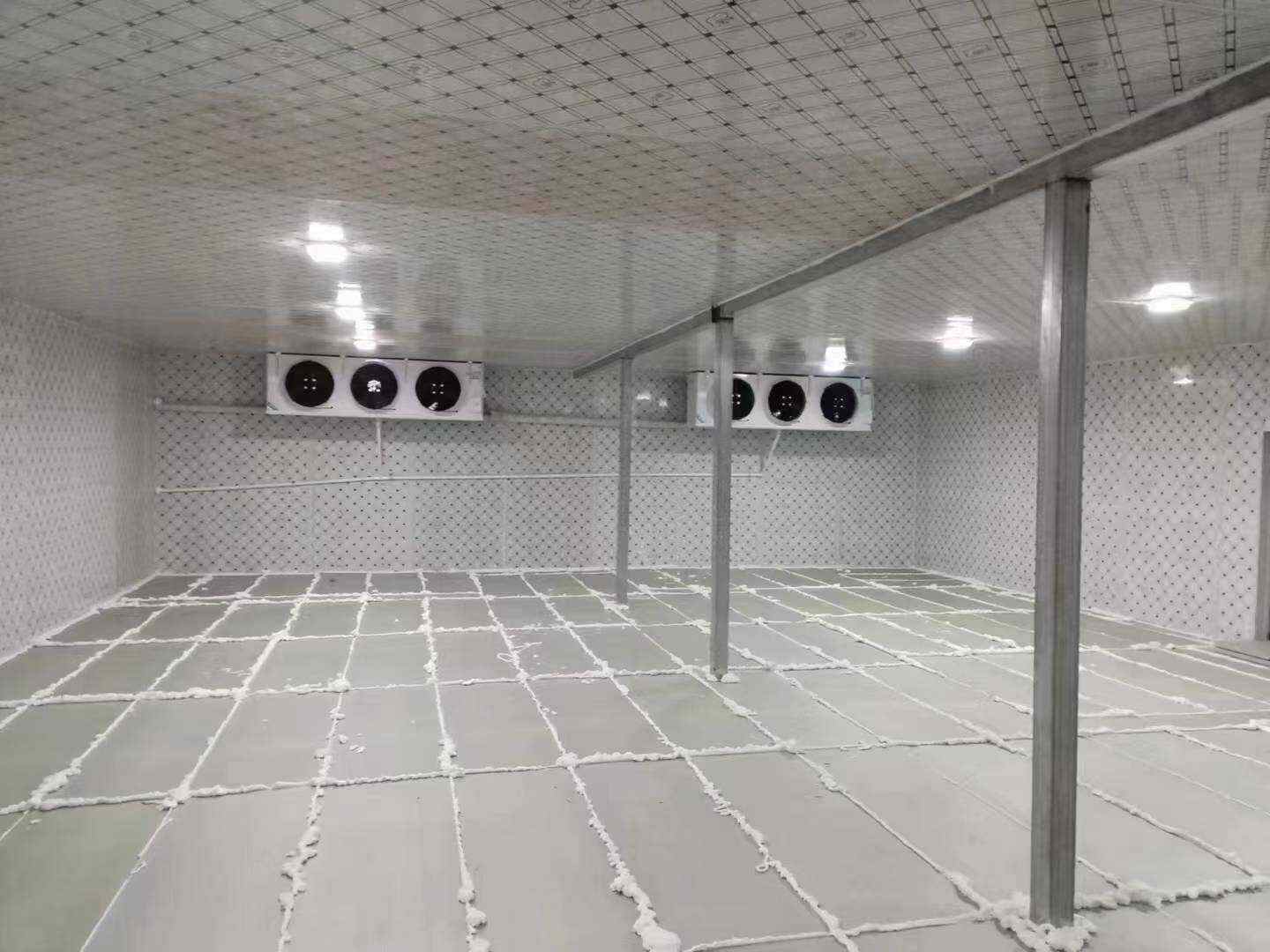

Customized Solutions: Meeting Diverse Needs

Enterprises in different industries and of different sizes have different needs for commercial refrigeration equipment. We can provide customized solutions according to the specific situation of customers.

For large food processing enterprises, we provide large - capacity customized cold rooms (100 - 50,000 + sq. ft.) equipped with dual - zone evaporation plates and CIP cleaning systems to meet the storage requirements of different kinds of food and ensure the hygiene standards in the production process. After a Nordic dairy adopted our 9GRW - 12 cold storage tank, it achieved 30% faster cooling (35°C→4°C in 2.5 hours), and the bacterial counts were as low as 4CFU/mL, successfully obtaining EU Quality Milk Certification.

For small retailers or community cold storage, our plug - and - play cold room kits are ideal choices. These modular cold storage components are easy to install and can be deployed in a short time to meet the needs of customers for rapid opening or expansion. At the same time, its compact design also greatly saves floor space and reduces operating costs.

Success Case: Energy-Saving Transformation of a Nordic Dairy Enterprise

Green Field Pastures is a leading Nordic dairy, facing the challenge of - 25°C winter low temperature and strict EU microbiological standards (total bacterial count ≤ 10CFU/mL). Before introducing our commercial refrigeration solutions, the enterprise's cold storage had high energy consumption, and product quality often fluctuated due to equipment failure.

After deploying our 9GRW - 12 cold storage tank and supporting intelligent management system, the enterprise has achieved remarkable results. Not only has the cooling speed increased by 30% to ensure the freshness of milk, but also 15% lower energy use has been achieved through variable - speed compressors. More importantly, its bacterial counts are stable at 4CFU/mL, fully meeting EU quality standards, and the competitiveness of its products in the market has been greatly improved.

In 2025, the new EU regulations have set a higher threshold for the commercial refrigeration industry, but they have also promoted technological innovation and upgrading of the industry. Our commercial refrigeration solutions provide enterprises with EU - standard compliant energy - efficient cold storage equipment with advanced energy - saving technologies, comprehensive compliance certifications, intelligent management systems and customized services. Whether you are a large food processing enterprise, a logistics and warehousing company or a small retailer, choosing our products can not only meet regulatory requirements but also reduce operating costs and enhance market competitiveness. Let's work together to move forward steadily on the road of green cold chain.

08.03, 2025

08.03, 2025