Top Products

09.27, 2024

09.27, 2024

Cold rooms and clean rooms share similarities in that both require precise control over airflow and temperature. However, while clean rooms must maintain an environment free from contaminants, dust, or dirt to ensure purity, cold rooms focus on maintaining very low temperatures to preserve their contents.

The structure of cold rooms varies depending on their specific use, but all cold rooms share certain fundamental characteristics, including their refrigeration systems. Despite the variety in refrigeration systems, their operation generally follows a standard approach.

Like clean rooms, cold rooms have essential components designed to maintain their required conditions, paying attention to even the smallest details.

Flooring

The choice of flooring for a cold room depends on its temperature and specific needs. Flooring must endure freezing temperatures, be easy to clean, support heavy equipment, and be slip-resistant, stainless, and non-absorptive. Polyaspartic and urethane coatings are effective as they cure quickly even in cold conditions. Additionally, if a cold room is connected to a clean room, the flooring must be seamless and tightly sealed to resist thermal shock.

Panels

Cold room panels are typically constructed with a core of either polyisocyanurate (PIR), which offers highly efficient insulation, or polyurethane (PU), made using uniform dispersion molding (UDM). These panels are designed for easy installation and transport, being manufactured in manageable sections.

In addition to PIR and PU, cold room panels may also be made from polystyrene, neopor, or compressed straw, each suited to specific cold room applications and installation methods. The key attributes of cold room panels include their lightweight nature, durability, and ease of handling.

Doors

In addition to the number of doors for a cold room, the quality and type of doors are crucial for accessing and maintaining the seal of the cold room. Several types of doors are used in cold rooms, including:

Horizontal sliding

Vertical sliding

Hinged

Service doors

Specialized doors

Fold-up

Cold Room Refrigeration System

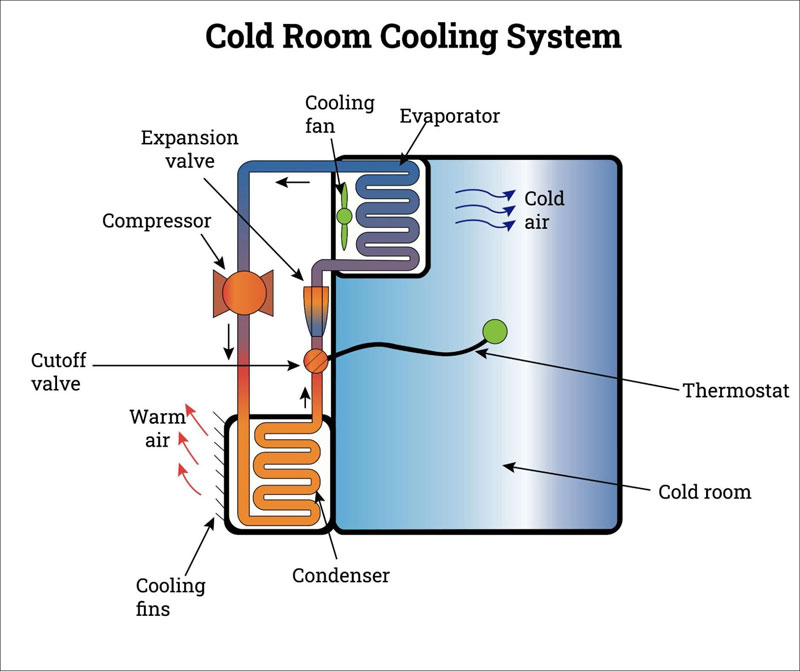

The temperatures in a cold room are maintained by a refrigeration system designed to meet its specific requirements. Key components of a refrigeration system include a compressor, condenser, expansion valve, evaporator coils, and circulation fans. Additionally, the system uses refrigerant gases, such as ammonia, freon, or CO2, to achieve and maintain the desired temperature.

Compressor – The compressor is the heart of the refrigeration system. It compresses the refrigerant gas to increase its temperature before it enters the condenser.

Condenser – The condenser is a heat exchanger where heat from the refrigerant is transferred to a flow of water that goes to a cooling tower. In the condenser, the refrigerant is under constant pressure, which is controlled and monitored. The hot gas of the refrigerant is cooled to a liquid.

Expansion Valve – In the expansion valve, the refrigerant expands, releases pressure, and experiences a temperature drop. The refrigerant leaves the expansion valve as a liquid vapor mixture. Expansion valves maintain the pressure differential and control the amount of refrigerant that enters the evaporator.

Evaporator – In the evaporator, the refrigerant is at a lower temperature, evaporates, and absorbs heat. From the evaporator, the refrigerant enters the compressor where the process begins again.

Cool Fan – The cooling fan circulates the low temperature of the refrigerant in the evaporator into the cold room to help maintain the set temperature of the cold room. They ensure even distribution of the cold air and reduce any temperature variations.

Refrigeration systems for cold rooms come in various configurations. Monoblock systems are compact and fit through a wall or ceiling of the cold room. Split or remote systems feature an external condenser and an evaporator located inside the cold room. The refrigeration system can be integrated into the walls, ceiling, or floor of the cold room, or be part of a larger, all-inclusive system.

Regardless of the specific type or use, essential factors for cold rooms include a tight seal, consistent temperature control, structural stability, effective insulation, and a reliable refrigeration system. Each of these elements must be meticulously planned and engineered to ensure the cold room's success.