Introduction: Why Does Your Industry Need Professional Refrigeration Equipment?

In agriculture, medical care, industry, commerce and other fields, refrigeration equipment has become a key infrastructure to ensure product quality and operational efficiency. According to industry research, more than 80% of enterprises will ask the following core questions when searching for refrigeration equipment:

- How to choose a cold storage system that suits their needs?

- There are many brands of condensing units, which are more reliable?

- Is the maintenance cost of the evaporator controllable?

- How to achieve high efficiency and energy saving for cold chain logistics equipment?

- What are the special requirements for refrigeration equipment in special industries (such as medical treatment, aerospace)?

This article will focus on these high-frequency search questions, combined with industry cases and product recommendations, to provide you with a one-stop solution.

I. How to Choose the Right Cold Storage System?

1. Clarify Industry Needs and Temperature Range

Different industries have significantly different temperature requirements for cold storage:

- Food industry: Preservation of fruits and vegetables (0-15℃), freezing of meat (-18℃), refrigeration of dairy products (2-6℃)

- Medical industry: Vaccine storage (-70℃), pharmaceutical cold chain (2-8℃), biological sample bank (-196℃)

- Industrial field: Semiconductor raw materials (-40℃), rocket fuel (-183℃)

Cases: Apple growers in Shandong reduced the loss rate of apples from 30% to 5% by using gradient cooling technology; the mango industry in Hainan achieved stable annual supply through a 12℃ constant temperature warehouse, and price fluctuations were reduced by 60%.

2. Consider Scale and Energy Efficiency

- Small enterprises: Modular cold storage can be selected, with a short installation cycle (7-15 days) and 20% lower energy consumption

- Large enterprises: Distributed cold storage networks (such as Yili's 72-hour national distribution) can improve supply chain efficiency

3. Compliance and Certification

The medical industry needs to comply with GSP certification, and the industrial field needs to meet the ASME B31.5 standard. For example, a multinational pharmaceutical company achieved a full-process temperature difference of ≤0.5℃ through a 2-8℃ precision temperature-controlled cold storage, and the drug loss rate was only 0.03%.

II. Comparison of Condensing Unit Brands: Performance, Energy Efficiency and Cost Analysis

1. Tecumseh: 85 Years of Professional Experience

- Advantages: Full range coverage (small indoor to large outdoor), low noise design (≤65dB)

- Application scenarios: Convenience stores, restaurants, small and medium-sized food processing plants

2. AAON: Expert in High Efficiency and Energy Saving

- Technical highlights: Variable capacity compressor (30% energy saving), AHRI certification (reliability guarantee)

- Typical case: A central kitchen of a catering company introduced AAON condensing units, and the sorting efficiency was increased by 300%

3. Copeland: Innovative Technology Leader

- Product line: X series (medium and low temperature environment), T series (transportation application)

- Data support: The coefficient of performance (COP) is 15% higher than that of traditional products, and the maintenance cost is reduced by 25%

III. Evaporator Maintenance Cost and Life Management

1. Common Maintenance Problems and Solutions

- Frosting problem: EVAPCO's SST LE series adopts Cross Cool™ inner tube enhancement technology to reduce frosting frequency (maintenance cycle extended to 3 months)

- Corrosion protection: 304L stainless steel pipe + aluminum fin design, suitable for high humidity environments (such as seafood cold storage)

2. Cost Control Strategies

- Preventive maintenance: Regular cleaning (recommended once a quarter) can extend the evaporator life to more than 15 years

- Intelligent monitoring: Install temperature sensors (accuracy ±0.1℃) to warn of faults in real time

IV. High Efficiency and Energy Saving Solutions for Cold Chain Logistics Equipment

1. Cross-border Cold Chain and Transportation Equipment

- Marine refrigerated containers: Chilean cherries achieved a 28-day freshness period through -1℃ refrigerated containers, and China's imports increased by 25% annually

- Land transportation equipment: Copeland T series condensing units are specially designed for transportation, with 40% improved shock resistance

2. New Retail and Front-end Warehouses

- Hema Fresh case: The front-end cold storage network realizes 30-minute delivery, and the loss cost is reduced by 40%

- Technical trend: The Internet of Things (IoT) monitoring system can track temperature and humidity in real time, and the abnormal response time is <5 minutes

V. Customized Solutions for Special Industries

1. Medical Field

- Ultra-low temperature storage: Sinopharm Group's -70℃ cold storage has a storage capacity of 500 million doses, ensuring the vaccine supply chain

- Blood products: 2-8℃ cold storage increases plasma stability by 90%, and Shanghai Blood Center has an annual turnover of 300,000 units

2. Aerospace and New Energy

- Liquid hydrogen storage: -253℃ cold storage increases the density of liquid hydrogen by 800 times, and China Energy Group helps the hydrogen energy strategy

- Rocket fuel: The -183℃ liquid oxygen storage tank of the Fifth Academy of Aerospace ensures that the filling error is <0.1%

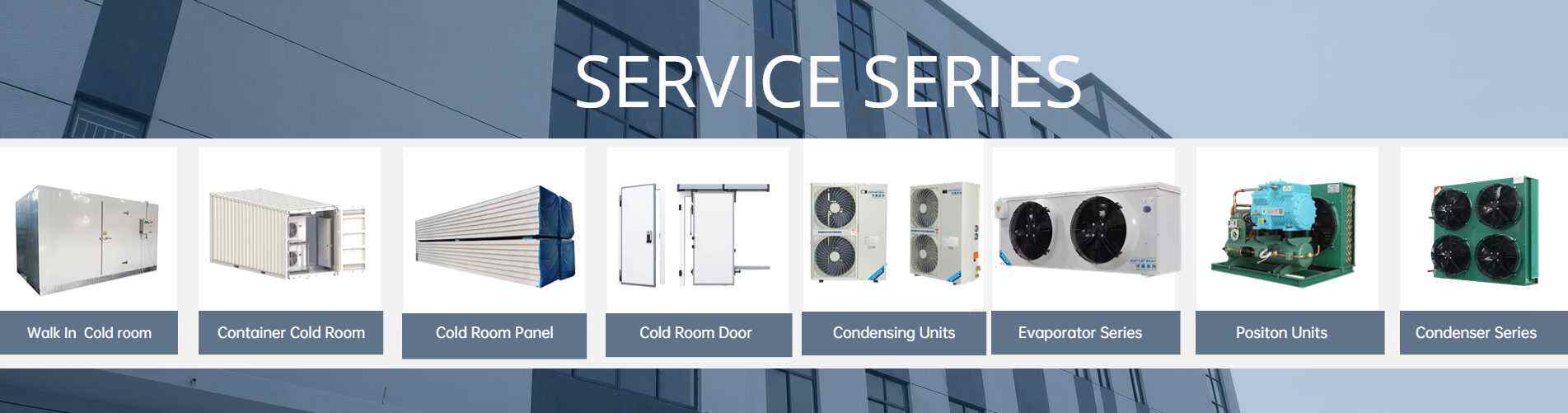

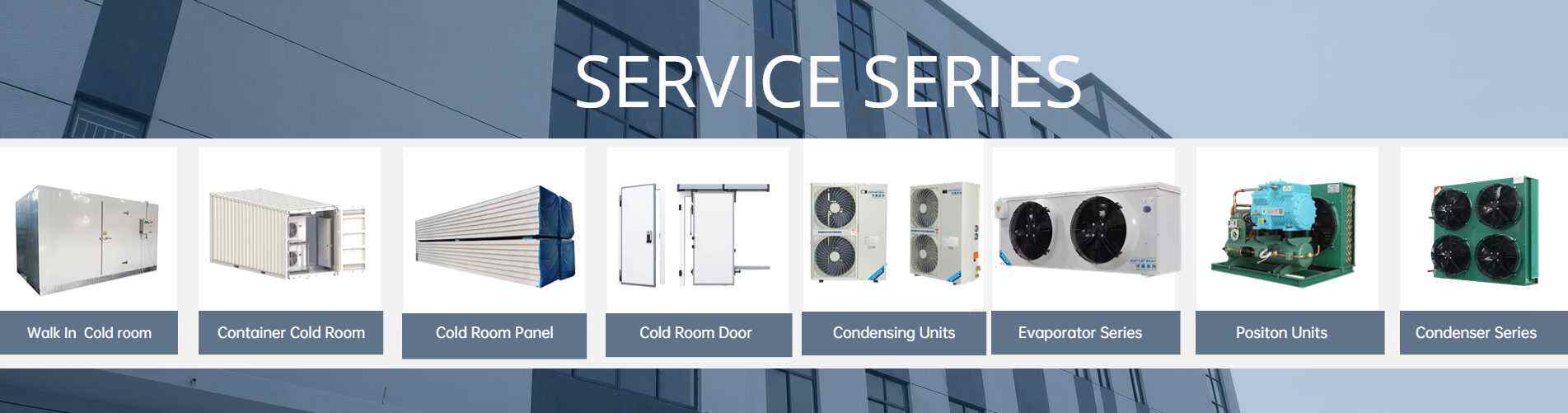

VI. Brand Recommendations and Service Support

1. Comprehensive Solution Providers

- Heatcraft: Full range of condensing units (1/2-100 horsepower), 304 stainless steel corrosion-resistant design

- EVAPCO: SST LE series evaporators (ASME certified), AMCA tested fans (low noise + high efficiency)

2. Full Life Cycle Services

- Installation support: Heatcraft provides pre-installed expansion valves, reducing installation time by 50%

- After-sales guarantee: Tecumseh provides a 5-year warranty on core components and 24-hour response service

Conclusion: Choose Professional Brands for Efficient Refrigeration

The choice of refrigeration equipment directly affects the operating costs and product quality of enterprises. By clarifying industry needs, comparing brand performance, and optimizing maintenance strategies, enterprises can significantly improve efficiency and reduce risks. Contact our xueyun expert team immediately to obtain customized solutions and start a new era of intelligent refrigeration!

07.28, 2025

07.28, 2025