0 installation and debugging + unlimited expansion + full-scenario adaptation: a must-see cold chain upgrade solution for cross-border merchants in 2025

Introduction: The Flexibility Revolution in Global Cold Chain Market

In 2025, global cold chain logistics demand is surging. Fresh e-commerce, pharmaceutical distribution, agricultural pre-cooling and other scenarios have raised higher requirements for immediate deployment capabilities of cold storage facilities. Traditional fixed cold rooms face pain points such as long installation cycles (average 2-3 months), high renovation costs (migration costs account for over 30% of initial investment), and strong geographical restrictions. Xueyuncold, a leading Chinese cold storage equipment manufacturer, has launched embedded mobile cold rooms that are redefining industry standards with the innovative concept of "plug-and-play, modular design, and full-scenario adaptation".

I. Technological Innovation: Redefining Core Values of Mobile Cold Rooms

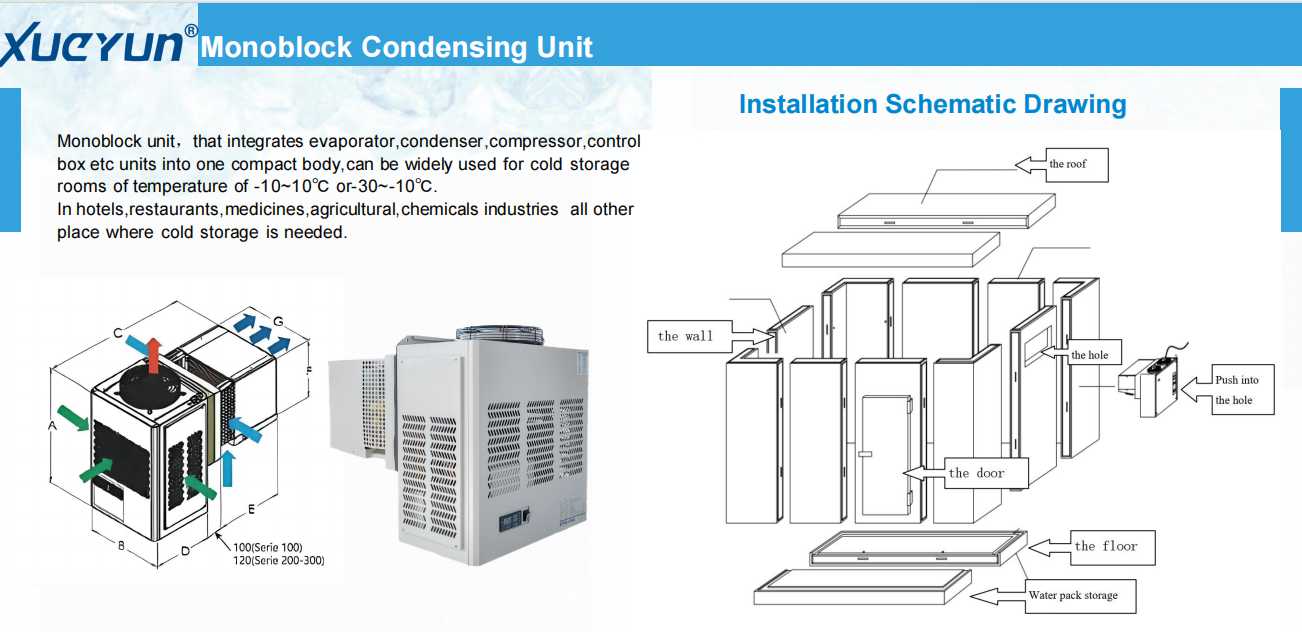

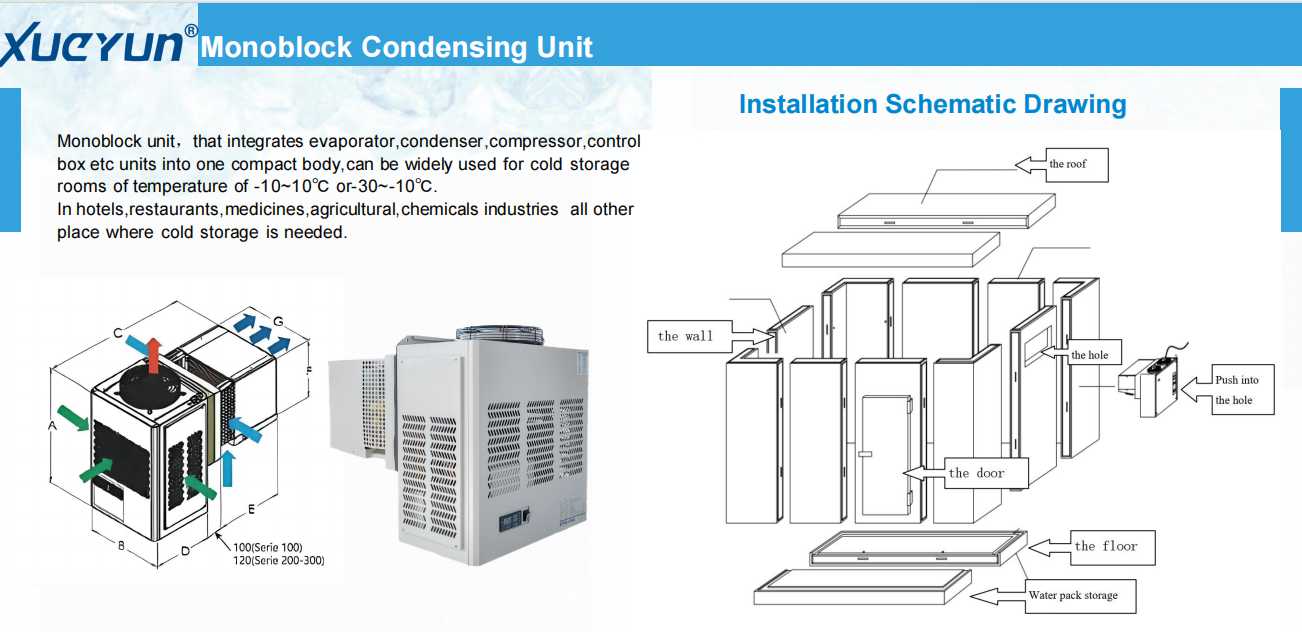

1. Disruptive Design of Embedded Integrated Units

Xueyuncold's XC-M Series embedded mobile cold rooms adopt integrated technology combining condensing units with cold room bodies. No on-site pipe welding or circuit debugging is required, and the set temperature can be reached within 30 minutes after power-on. Compared with traditional split-type cold rooms, installation time is reduced from 15 days to 1 hour, and labor costs are lowered by 80%. Equipped with DC inverter compressors, the units maintain a Coefficient of Performance (COP) ≥ 2.8 across a wide temperature range of -25℃ to +15℃, saving 35% more energy than traditional equipment.

2. Modular Structure Enables Infinite Expansion

The cold room body uses 50mm thick polyurethane sandwich panels (thermal conductivity 0.022W/(m·K)) with a patented locking system for quick assembly. Standard units (3m×2m×2.5m) can be used independently or horizontally expanded to 200㎡, meeting multi-level needs from family workshops to large warehouses. At a seafood market in Sydney, Australia, 80㎡ temporary cold storage was built within 2 hours by combining 6 modules, increasing daily processing capacity by 400%.

II. Scenario Revolution: Unlocking New Possibilities in Global Cold Chain

1. Agricultural Scenario: From Farm to International Markets

At a longan planting base in Chiang Mai, Thailand, Xueyuncold mobile cold rooms are directly deployed in orchards. Pre-cooling (from 32℃ to 4℃) is completed within 1 hour after harvesting, extending longan shelf life from 7 days to 21 days and increasing export premium rate by 25%. Equipped with solar power modules, the units can operate continuously for 72 hours in areas without grid coverage, solving the problem of unstable power supply in Southeast Asia.

2. Commercial Scenario: Flexibly Responding to Fluctuating Consumer Demand

A supermarket chain in Los Angeles, USA uses XC-M Series to cope with holiday promotions, quickly expanding cold storage capacity through rental. A single unit can be deployed within 48 hours at a rental cost only 1/5 of building a new fixed cold room. The built-in intelligent temperature control algorithm automatically adjusts cold room temperature based on sales data, reducing fresh product loss rate from 8% to 3.2%.

3. Medical Scenario: Precisely Ensuring Transportation of Life-saving Supplies

In African malaria prevention projects, Xueyuncold mobile cold rooms are equipped with GPS positioning and remote monitoring systems to maintain a constant temperature of 2-8℃ for anti-malarial drugs during transportation. The equipment has passed WHO PQS certification, and in field tests in Nigeria, drug validity period was extended by 18% while transportation loss rate dropped from 12% to 1.5%.

III. Cost Revolution: Reconstructing Whole-life Cycle Value

1. 50% Reduction in Initial Investment

XC-M Series adopts factory prefabricated production, saving 30% material costs and 40% labor costs compared with traditional cold rooms. For a 100㎡ cold room, traditional solutions require 150,000investment,whileXueyuncold′ssolutiononlyneeds

2. Continuous Optimization of Operating Costs

Units feature built-in AI energy management systems that automatically adjust refrigeration strategies by analyzing historical data. At a dairy factory in Saudi Arabia, the equipment consumes only 280kWh per day, 42% less than traditional solutions. Combined with photovoltaic power supply systems, it achieves zero-carbon operation.

3. Residual Value Recovery Enhances Asset Efficiency

With standardized interface design, cold room bodies and units can be 100% reused during migration. At a palm oil processing plant in Malaysia, through multiple migrations and reuse, the actual depreciation rate of equipment decreased from 15% to 8% annually, shortening the investment payback period to 2.1 years.

IV. Quality Assurance: Global Commitment from Design to Service

1. Extreme Environment Adaptability Verification

With IP55 protection rating certification, it can operate stably in harsh environments with 95% RH humidity and 0.5g/m³ dust concentration. In low-temperature tests in Vancouver, Canada, the equipment maintained cold room temperature at -25℃±0.5℃ even when the external temperature dropped to -35℃, reducing defrosting energy consumption by 30%.

2. Global Service Network Support

Xueyuncold has established 12 spare parts centers worldwide, providing 7×24-hour response service. In the European market, 90% of faults can be repaired within 48 hours, and with remote diagnostic systems, preventive maintenance coverage reaches 95%.

V. Benchmark Cases: Successful Practices of Global Users

- Brazilian beef exporter: By deploying 4 XC-M cold rooms, achieved full temperature traceability from slaughter to port, successfully entering high-end EU markets with 40% export volume growth.

- German restaurant chain: Adopted rental model to quickly expand cold chain capacity, reducing single-store equipment investment cost by 60% and increasing food freshness rating to 4.8/5.

- Indian agricultural cooperative: Used mobile cold rooms for mango pre-cooling, reducing loss rate from 15% to 5% and increasing farmers' annual income by $2,000 per household.

Conclusion: Choose Xueyuncold to Embark on Cold Chain 2.0 Era

In the critical period when global cold chains are transforming towards flexibility, intelligence, and low-carbonization, Xueyuncold's embedded mobile cold rooms provide disruptive solutions for food, pharmaceutical, agricultural and other industries with core advantages of plug-and-play, modular expansion, and full-scenario adaptation. Whether you need temporary storage, emergency support or cross-border transportation, Xueyuncold can help you seize new opportunities in the cold chain market with excellent performance of fastest 2-hour deployment, minimum 30% energy consumption, and longest 15-year service life.

Visit Xueyuncold official website now to get a free mobile cold room deployment plan and experience the innovative power of next-generation cold chain technology!

08.13, 2025

08.13, 2025